You'll want an Ann Arbor builder who understands Michigan's unique soil conditions and weather challenges-and designs building systems and infrastructure to Michigan Residential Code. We confirm zoning, setbacks, ROW, and utilities, then produce comprehensive building plans. Expect energy-efficient construction (≤1.5 ACH50), advanced climate control and sustainable features, Class 4 roofing, and vapor‑open WRBs. We provide detailed estimates and quality assurance, and explicit protection plans. See how this process ensures smooth project execution and faster permits.

Important Points

- Established Ann Arbor expertise: zoning, setbacks, tree protection, and right-of-way compliance to eliminate unexpected delays and budget adjustments.

- Regional construction mastery: managing difficult soil types, elevated water tables, frost-depth foundation systems, and state-mandated drainage and waterproofing standards

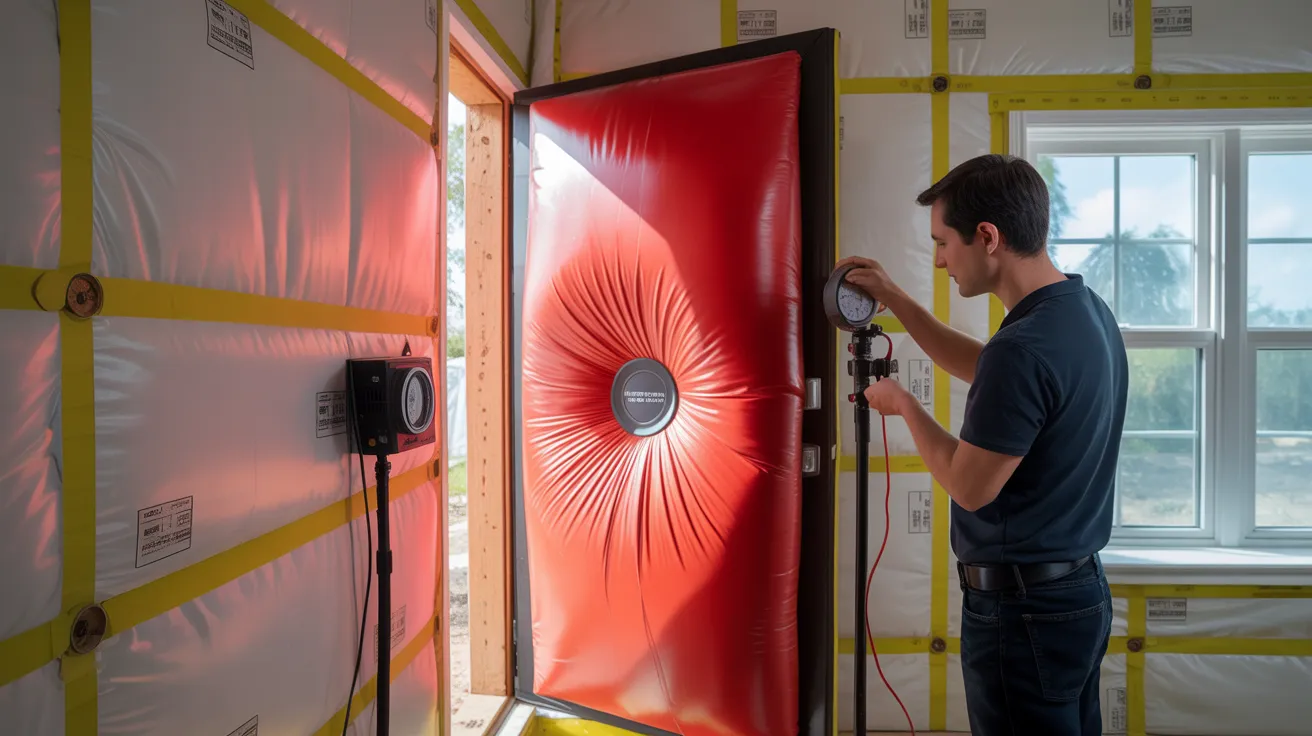

- Energy-forward specifications: airtight envelopes at ≤1.5 ACH50, advanced cold-climate heat pump systems, ERVs, solar-ready roof designs, and HERS-verified performance testing.

- Complete design-build: offering comprehensive design documentation, incorporating unified building systems and infrastructure, and thorough system commissioning.

- Comprehensive quality control and timeline management: standardized quality testing, key progress reviews, strategic supply chain coordination, and clear weekly progress reports through project completion.

Why Local Expertise Matters in Ann Arbor

While design vision guides a custom home, regional knowledge guarantees it is constructed properly in Ann Arbor's distinct conditions. You'll navigate heavy clay soil, high water tables, and frost line specifications with a builder who understands site drainage, vapor barriers, and foundation waterproofing per Michigan Residential Code. Area specialists calibrate foundations, footings, and thermal barriers to resist freezing and thawing and maintain seasonal construction timing that safeguards schedules and materials.

They'll coordinate building mass, setbacks, and architectural details with the neighborhood's character while handling authorization, tree conservation, and right-of-way compliance. You get precise snow-load specifications, energy code adherence, and HVAC sizing optimized for humidity changes. Construction employs qualified contractors and inspectors, minimizing change orders. Infrastructure coordination, stormwater control, and erosion protection are correctly ordered, guaranteeing your house operates effectively, meets compliance requirements, and integrates with its surroundings.

Custom Home Design: Understanding the Process

Prior to breaking ground, you have to determine scope, budget, and program, then advance through schematic design, design development, and permit-ready construction documents. Starting with comprehensive site assessment to analyze property boundaries, service lines, sun patterns, water flow, ground composition, and tree locations, ensuring the footprint and elevations align with actual site conditions. Through client workshops, you establish project requirements-energy targets, durability metrics, and accessibility needs-and specify building components (mechanical systems, building shell, glazing) to meet them.

Throughout schematic design, you refine various plan iterations and building mass, while validating structural feasibility and escape paths. In the design development stage, you establish construction assemblies, choose materials, align structural, MEP, and low-voltage layouts, and finalize fixture schedules. The process concludes with detailed construction documents: precisely dimensioned plans, sections, details, and specifications that are thoroughly coordinated, constructible, and ready for budgeting and construction scheduling.

Understanding Zoning Laws, Licensing, and Property Selection

Armed with a complete set of coordinated construction documents, you proceed with the regulatory requirements: confirming zoning requirements, acquiring permits, and selecting a suitable lot that accommodates the program. Verify the zoning designation, purpose, setbacks, height restrictions, lot coverage, floor area ratio, and frontage. Examine overlays, floodplains, and tree conservation. Validate access, driveway spacing, and fire apparatus access. Obtain boundary and topographic surveys to identify utilities, wetlands, and utility easements. Complete soil testing and geotechnical borings to determine bearing capacity, groundwater, and foundation type.

Meet with the City of Ann Arbor Planning and Building staff for initial planning assistance. Compile required submittals: architectural plans, site drawings, drainage specifications, erosion control measures, and engineering documentation. Process required permits for building, stormwater, and right-of-way authorizations. Schedule site reviews and specialized assessments, and track all authorizations.

Green Construction Methods and Energy Performance

As you balance aesthetics and program requirements, you should implement sustainability strategies that align with or go beyond Michigan Energy Code (MEC 2015/ASHRAE 90.1 as locally amended) and Ann Arbor's carbon-reduction targets. Focus on developing a tight thermal envelope with blower-door specifications ≤1.5 ACH50, seamless outer insulation, and thermally broken components. Select high-performance windows with U-factors ≤0.25 and SHGC adjusted for passive solar on south façades with carefully calculated overhangs.

Start by properly sizing HVAC systems using ACCA Manual J/S/D, and proceed with implementing advanced cold-climate heat pumps, ERVs adjusted to ASHRAE 62.2, and intelligent controls. First reduce loads by optimizing orientation, performing air sealing, and incorporating ductless distribution. Configure for net zero potential using all-electric systems, electric vehicle charging capabilities, heat pump water heating solutions, and a solar-ready roof at optimal tilt/azimuth. Verify performance through system commissioning and RESNET HERS verification.

Quality of Materials, Construction, and Craftsmanship

We utilize premium building materials designed for Michigan's extreme freeze-thaw cycles, compliant with IRC, IBC, and local Ann Arbor amendments. We deliver expert craftsmanship practices - tight tolerances, correct fastening schedules, moisture management details, and factory-certified assemblies. You gain comprehensive quality control with documented inspections at all major building milestones.

Superior, Enduring Materials

Select premium, durable materials from the outset to ensure performance, durability, and code compliance. You'll minimize lifecycle costs, satisfy Michigan Residential Code requirements, and reduce upkeep.

Start with structural elements initially: employ kiln-dried, graded lumber or LVLs for dimensional stability; specify corrosion-resistant fasteners (ASTM A153 or A653) within wet locations; and pick concrete with appropriate air entrainment and a minimum 4,000 psi compressive strength for cold weather resilience. For outer structures, go with fiber-cement or Recycled composites for exterior siding, Class 4 impact-rated roofing materials, and PVC/ABS where allowed by code, with chemically bonded joints.

For maximum thermal resistance and humidity management, pair exterior continuous insulation and vapor-permeable weather barriers. Look into Hempcrete blocks for non-structural infill to enhance thermal storage and moisture control. Complete with Class A, low-VOC interior treatments and WR-rated external assemblies.

Superior Craftsmanship Criteria

Although materials form the basis, expertise is essential for code compliance, safety, and optimal performance in the field. We deliver properly aligned and squared components; we confirm specifications at frame construction, sheathing application, and trim work. Our teams implement expert craftsmanship where they create value-including precise millwork fitting-while following product guidelines and the Michigan Residential Code. Attachment methods, corrosion resistance, and surface prep meet published guidelines to preserve structural stability and warranty compliance.

You obtain clean penetrations, well-executed flashing, and perfect reveals at windows, doors, and fixtures. Utility penetrations coordinate with load-bearing elements and fire barriers. Finishes achieve established finishing requirements: mil-thickness, adhesion, and sheen uniformity. Tile surfaces are level, grout joints consistent, and sealants tooled for movement, durability, and weather resistance.

Stringent Quality Assurance

Because quality must be demonstrated, not presumed, we execute a comprehensive QA/QC program from start to finish. You'll see comprehensive reviews, preliminary meetings, and sourcing validation with complete procurement click here documentation. We confirm code conformance against the Michigan Residential Code and manufacturer specifications before proceeding to fabrication.

At each milestone, we execute detailed site inspections encompassing crucial stages: foundations, framing, MEP rough-in, air/water barriers, insulation, and finals. We utilize specialized tools including moisture meters, torque verification, blower-door, duct-leakage, and IR thermography to validate performance specifications. All work adheres to ACI, APA, and AWI specifications. When issues arise, we implement remediation procedures, requiring re-verification and formal approval. Craftsmanship is verified with thorough checklists that cover fastener schedules, flashings, clearances, and finishes. Complete records is prepared in a closeout package containing warranties, test reports, and as-builts.

Smart Home Integration and Modern Amenities

Throughout the entire process, from initial wiring to final setup, we implement a code-compliant framework that coordinates equipment, energy distribution, and connectivity to your lifestyle and Michigan codes. We configure low-voltage pathways for surveillance equipment, security controls, and health monitoring devices, segregate circuits for clean power, and specify grounded surge protection per NEC. You'll receive integrated smart controllers that support voice control and AI automation, with hardwired backbones for reliability and secured Wi‑Fi 6E coverage.

We program ambient lighting scenes with daylight-responsive dimming systems, link ventilation to IAQ data, and incorporate hydronic or forced-air controls for precise temperature control. Wiring architecture delivers 10 GbE, while automated lighting systems and window treatments align with load calculations. System validation confirms backup systems, controller updates, data protection, and network architecture.

Transparent Budgeting, Bids, and Project Timelines

You should insist on detailed, broken-down quotes that break down labor, materials, allowances, contingencies, permits, and inspection fees, so cost exposure is traceable. Request a realistic timeline with checkpoints tied to inspection requirements (foundation, rough-in MEP, insulation, drywall, final), each with specific timeframes and flexibility. Verify that modification procedures specify pricing method, approval path, and schedule impacts prior to beginning modifications.

Clear, Itemized Bids

Start with a line-item bid that separates all aspects into measurable components-such as demolition, foundation, framing, MEP rough-ins, insulation, finishes-each connected to labor, materials, unit costs, allowances, and contingencies. You'll find quantities, specs, and code references where necessary, so you can verify compliance and scope. Require line item estimates that cite drawings, details, and product data (e.g., R-values, PSI, fire ratings, and fixture schedules). Insist on unit pricing for excavation, cubic yards of concrete, linear feet of footing drain, square footage of drywall, and per-fixture MEP costs.

Track every allocation with brand, model, and installation details. Include backup allowances as distinct, percentage-driven lines connected with specific risk types and change management protocols. Request exceptions and alternatives in written format to minimize scope creep and protect your budget.

Timeline and Project Milestones

Although bids establish expenses, maintaining schedule discipline keeps construction on schedule-set milestone dates aligned with approvals, lead times, inspections, and essential path elements. You'll map out site work, foundations, framing, utility rough-ins, insulation, drywall, finishing, and commissioning as quantifiable project checkpoints with specific start/completion periods. Arrange for early utility installation and surveys to minimize changes. Set firm procurement deadlines for materials with extended delivery times-windows, trusses, panels, and fixtures-so deliveries occur before installation by at least one inspection cycle.

Create a fundamental schedule including contingencies for weather delays and inspection follow-ups. Define acceptance criteria: passed footing inspection, passed rough-in, blower-door test results, and occupancy certification. Maintain weekly client communication with look-ahead schedules and deviation records. Align trade availability with inspection schedules. Organize handover procedure: completion of punch list, warranty materials, maintenance and operations documentation, and final clean.

Professional Partnerships: Architects, Designers, and Trade Allies

The success or failure of a custom home hinges on handoffs, demanding well-documented teamwork between architects, interior designers, engineering specialists, and trade partners, following code requirements from day one. The focus remains on architectural alignment using BIM-enabled drawing reviews, clash detection, and documented approvals that align with Michigan Residential Code, NEC, and energy code specifications. Comprehensive specifications are provided outlining important aspects including tolerances, fastening schedules, vapor control layers, firestopping, and egress requirements.

By maintaining strong Trade relationships, you conduct pull-planning meetings, secure sequencing (covering foundation, framing, MEP roughs, insulation, drywall), and distribute look-ahead schedules. You mandate RFIs, shop drawings, and product data with listing/labeling verification. Field QA/QC consists of pre-pour, rough, insulation, and pre-close inspections, plus verification reports: blower door, duct leakage, and equipment startup checklists. Decision tracking is maintained with version control.

After-Build Support and Warranty Coverage

Following handoff completion and code inspection finalization, we maintain support via a comprehensive warranty program that's as disciplined as construction. You'll be provided with a written warranty matrix specifying coverage periods for structure, building envelope, systems, and finishes, aligned with Michigan code and manufacturer requirements. We document product registrations, serial numbers, and maintenance records to ensure compliance with Service Protocols and maintain manufacturer warranties.

You have the option to submit tickets using the portal or through a phone call; we triage by life-threatening situations, leak issues, and comfort impacts. Our technicians conduct root-cause diagnostics before repairs, documenting components, pictures, and solutions. Seasonal tune-ups ensure HVAC static pressure, combustion system safety, GFCI/AFCI performance, and drainage grading. We coordinate Warranty Transfers during the sale, updating manuals, permits, and release of liens, ensuring continuity, clear SLAs, and measurable closeouts.

Frequently Asked Questions

How Do You Manage Conflict Resolution Among Homeowners and the Build Team?

You manage conflict resolution by developing a written issue log, organizing quick stand-ups, and using documented change orders. You resolve disagreements with clear cost/schedule impacts and referencing specs, drawings, and code sections. You outline expectations at kickoff: authority for decisions, RFI turnaround, and tolerance standards. You verify facts on-site, proposing compliant alternatives, and recording agreements via meeting minutes. You bring up per a pre-set ladder, then close out with punch-list validation and client sign-off.

What Insurance Coverage Do You Carry and Require From Subcontractors?

Like a well-tuned safety net, you maintain General Liability and Builder’s Risk to protect the project’s spine and skin. You also maintain workers’ compensation and commercial auto. You require subcontractors to submit matching General Liability (min. $1M/$2M), workers’ comp, and auto, designating you as additional insured with primary, noncontributory wording and waiver of subrogation. You confirm COIs before mobilization, oversee expirations, and copyright contract indemnity, ensuring code-compliant, risk-managed site operations.

Are you able to provide up-to-date client references as well as options for site visits?

Yes. You’ll receive recent client references with comprehensive contact details and project scopes. We’ll plan site tours of ongoing builds, organized to meet OSHA safety requirements and access protocols. You’ll witness framing, MEP rough-ins, envelope details, and finish quality. We’ll offer punch lists, schedule dashboards, and QA/QC checklists to ensure processes. You can assess documented client testimonials, warranty records, and change-order logs to evaluate communication, cost control, timeline adherence, and code compliance.

How Can You Ensure the Site and Neighbors Are Protected During Construction?

One safeguard the site and neighbors by setting up perimeter site fencing, displaying OSHA signage, and upholding secure access. We implement dust control with moisture control, covered stockpiles, and wheel-wash stations. You control noise by organizing high-decibel tasks within ordinance windows and using baffled equipment. You mitigate runoff with silt fence, inlet protection, and stabilized construction entrances per EPA SWPPP. One stage deliveries to avoid road blockage and maintain streets swept and lighting shielded.

What is the process for change orders and how long does approval take?

Cut once, measure twice. You provide a change request with budget implications, specifications, and scope. We run change management: verifying code compliance, quantifying schedule and cost, updating drawings, and obtaining signatures. Standard approval duration: Between 24 and 72 hours for minor changes, and 5 to 7 business days for structural, MEP, or permitting requests. After you e-sign the change order, we issue a revised schedule of values and CPM update, and subsequently implement it with tracked revisions and field verification.

Closing Remarks

You’re prepared to choose an Ann Arbor custom home builder who speaks the local code as a primary language. You’ll handle zoning with ease, ensure budgets in check, and let timelines flow smoothly. You’ll focus on high‑efficiency envelopes, appropriately mechanicals, and subtle materials that don’t seek attention. You’ll require clean documentation, clear bids, and proven assemblies. When small surprises arise, you’ll refer to adjustments. With the ideal partners, you’ll commission a home that functions, adheres to regulations, and lasts without problems.